LaseCPW

Coil Positioning Wagon

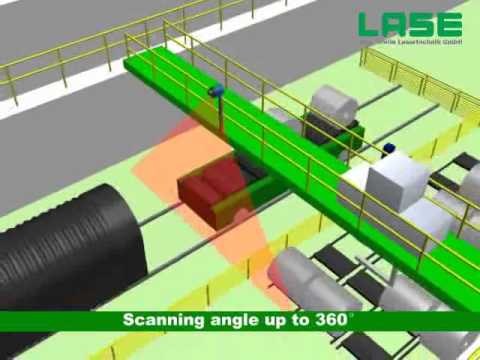

The LASE measuring system LaseCPW consists of a laser scanner that measures the position of coils on wagons in the Y and Z axis (cross travel and lift axis).

The Measuring System

The laser scanner is mounted to the crane at a 4 m distance from the centre of the train track. The measured data from the LASE system provides 3-dimensional images of the position of the coils on the wagons.

The positions of the coils and troughs are determined by a measurement drive of the crane over the wagons before loading or unloading. The crane travels at a constant speed over the wagons to be measured.

After completion of the measurement drive, the calculation of the coil and trough positions begins. The measurement result (positions of all coils in X, Y and Z direction) is sent to the crane PLC. The crane PLC sends the position data to the warehouse management system.

Using the coil position data, the warehouse management system can generate the travel orders for the automatic crane.

After completion of the measurement drive, the calculation of the coil and trough positions begins. The measurement result (positions of all coils in X, Y and Z direction) is sent to the crane PLC. The crane PLC sends the position data to the warehouse management system.

Using the coil position data, the warehouse management system can generate the travel orders for the automatic crane.

General Features

Automatic loading and unloading of wagons

Accurate coil and trough position detection

Gentle coil handling

Faster turnaround times

Robust measurement technology

Avoidance of damage

Automatic slab handling is also possible

Use of existing structures